In the ever-evolving world of material science, the development of advanced alloys has consistently played a pivotal role in improving industries ranging from aerospace to electronics. One of the latest innovations making waves is Tungsten Silver Alloy, a high-performance material that combines the strength and durability of tungsten with the electrical and thermal conductivity of silver. This new alloy is set to offer remarkable improvements in a variety of applications, making it an exciting breakthrough for both scientific research and commercial industries.

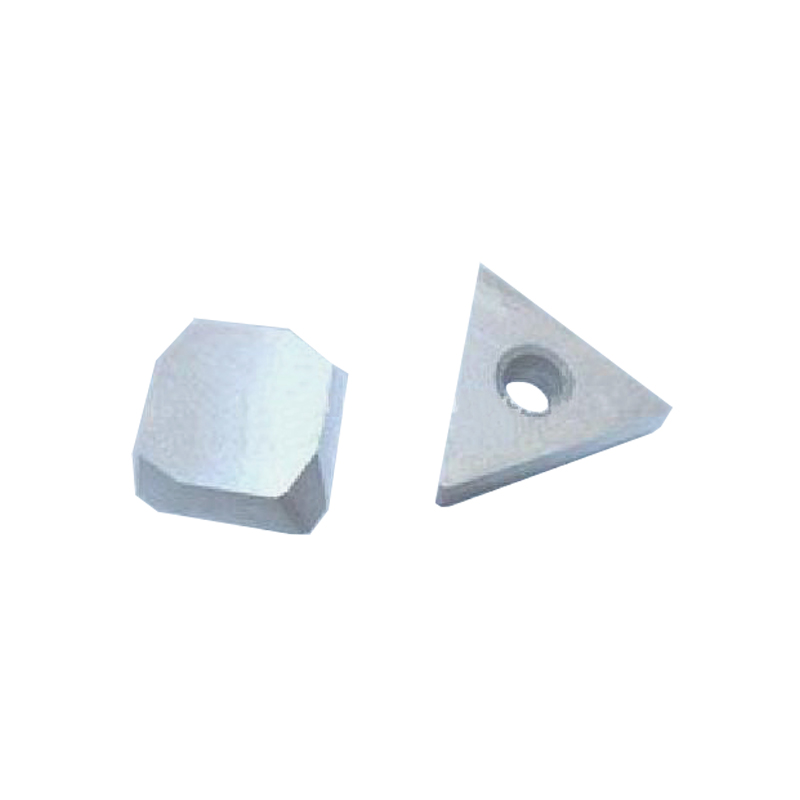

Tungsten Silver Alloy is a composite material consisting primarily of tungsten (W) and silver (Ag). Tungsten, known for its exceptional hardness, high melting point, and resistance to wear and corrosion, is often used in high-stress environments such as aerospace and heavy machinery. Silver, on the other hand, is celebrated for its superior conductivity, making it ideal for electronic applications.

By combining these two metals, Tungsten Silver Alloy offers a unique balance of properties that cater to both mechanical and electrical needs. The tungsten content gives the alloy its robustness, while the silver content significantly enhances its conductivity, making it an ideal choice for specialized electrical and high-temperature applications.

Silver is the best conductor of electricity, and when combined with tungsten, the resulting alloy retains much of its conductivity. This makes Tungsten Silver Alloy an excellent material for high-performance electrical components that require both durability and efficient heat dissipation.

Tungsten is one of the hardest materials on earth, and this characteristic is preserved in the Tungsten Silver Alloy. The alloy is incredibly resistant to wear and tear, making it ideal for applications that involve extreme mechanical stresses, such as in aerospace and defense industries.

Tungsten Silver Alloy also boasts excellent thermal stability, retaining its structural integrity even at extremely high temperatures. This makes it particularly useful in environments where materials are subjected to intense heat, such as in high-temperature furnaces, rocket nozzles, or electronic components that generate heat during operation.

+Tungsten is known for its resistance to corrosion, and this property is enhanced in the alloy. This means that Tungsten Silver Alloy is not only strong but also durable in harsh environments, including exposure to moisture, acids, and other corrosive agents.

The potential applications of Tungsten Silver Alloy are vast and diverse, making it a valuable material in several industries:

Due to its superior conductivity, Tungsten Silver Alloy is an ideal material for high-performance electrical connectors, switches, and contacts. The alloy’s durability ensures a long operational life in electronic devices, reducing the need for frequent replacements and minimizing downtime.

The combination of thermal stability, strength, and corrosion resistance makes Tungsten Silver Alloy highly suitable for the aerospace and defense industries. Components such as rocket nozzles, turbine blades, and high-temperature shielding can be manufactured using this alloy, ensuring they withstand extreme conditions without degradation.

Tungsten Silver Alloy’s ability to maintain its integrity under high stress and temperature makes it useful for certain medical devices. Its biocompatibility and durability make it suitable for implants, prosthetics, and other devices that require high-performance materials.

The alloy’s resilience at high temperatures makes it useful for industrial applications such as furnaces, electric arc welding, and other processes that require materials to withstand significant heat.

As researchers continue to explore the full potential of Tungsten Silver Alloy, there is a growing interest in developing even more specialized forms of the material. Ongoing advancements in production techniques, such as powder metallurgy and additive manufacturing, may lead to further improvements in the alloy’s properties, making it even more adaptable and efficient in a wider range of industries.

With its combination of strength, conductivity, and heat resistance, Tungsten Silver Alloy is poised to become an indispensable material in industries that demand the highest performance from their components. Its unique blend of tungsten’s toughness and silver’s conductivity makes it an essential addition to the material science toolkit, offering innovative solutions for a variety of complex engineering challenges.

Tungsten Silver Alloy is not just a new material but a significant advancement that could revolutionize multiple industries. As manufacturers and researchers continue to explore its applications, this alloy promises to be a game-changer in fields that require high durability, efficient energy use, and exceptional performance under extreme conditions. The future of Tungsten Silver Alloy is bright, and its impact will likely be felt across a wide range of sectors for years to come.