Tungsten silver alloy is a composite material composed of tungsten (W) and silver (Ag). It plays an important role in many industrial fields due to its unique physical and chemical properties. This alloy combines the high melting point and high strength of tungsten with the excellent electrical conductivity and thermal conductivity of silver, making it an ideal choice for many high-tech applications. Whether it is the electronics industry, aerospace or medical equipment manufacturing, tungsten silver alloy has won wide recognition for its excellent performance.

Tungsten has a melting point of up to 3422°C, which gives tungsten silver alloy excellent high temperature resistance. Even under extreme temperature conditions, this alloy can maintain structural stability and is suitable for key components in high temperature environments.

Excellent electrical and thermal conductivity

Silver is one of the best known metals for electrical and thermal conductivity. Tungsten silver alloy inherits this property, making it outstanding in application scenarios that require efficient electrical conduction and heat dissipation.

High strength and wear resistance

The hardness and strength of tungsten give tungsten silver alloy good mechanical properties, which can withstand high pressure and wear and extend service life.

Corrosion resistance

Tungsten silver alloy has strong corrosion resistance to a variety of chemicals, especially in acidic or alkaline environments, and is suitable for equipment manufacturing under harsh working conditions.

Machinability

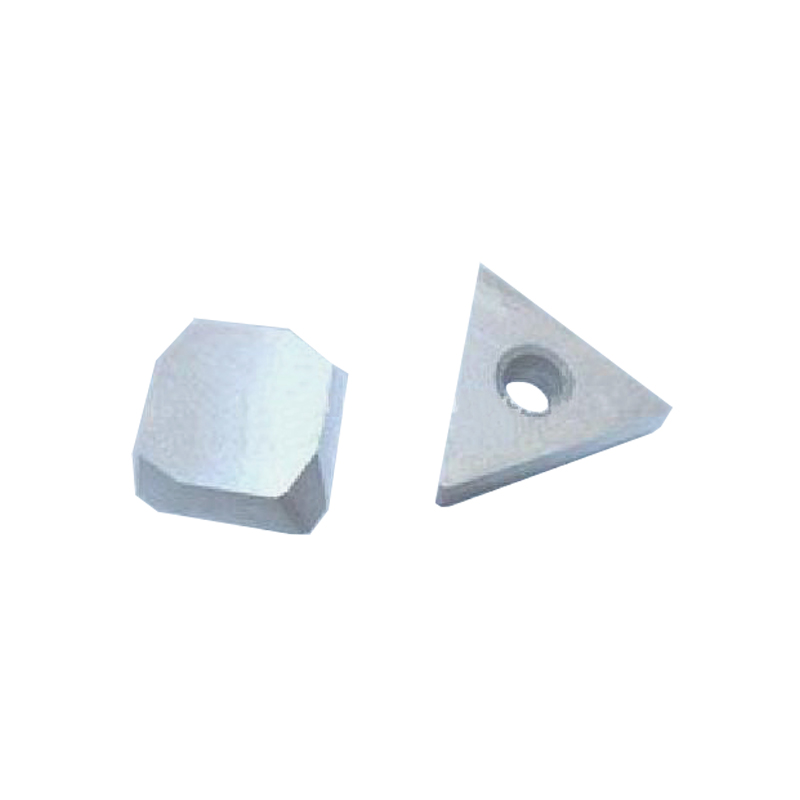

Although tungsten itself is hard and difficult to process, the processing performance of tungsten silver alloy has been significantly improved by combining with silver, and it can be made into parts of complex shapes by sintering, pressing, etc.

Application areas of tungsten silver alloy

Electronic industry

Electrical contact material: Tungsten silver alloy is often used to manufacture electrical contacts in high-voltage switches, circuit breakers and relays. Its resistance to arc ablation and welding makes it perform well in high-frequency current and high-voltage environments.

Heat dissipation components: Due to its excellent thermal conductivity, tungsten silver alloy is widely used in heat sinks and substrates of high-power electronic devices.

Aerospace

In the field of aerospace, tungsten silver alloy is used to manufacture rocket nozzles, engine components, and high-temperature resistant structural parts. Its high temperature resistance and high strength enable it to operate stably in extreme environments.

Military Industry and Defense

Tungsten silver alloy is used to manufacture armor-piercing cores, armor protection materials, and other key components of military equipment due to its high density and impact resistance.

Medical Equipment

Some precision instruments and equipment in the medical field (such as X-ray shielding materials) also use tungsten silver alloy because it can effectively shield radiation and has good processing performance.

Welding and Cutting

In the welding and cutting industry, tungsten silver alloy can be used as an electrode material, especially in resistance welding and electrospark machining, where its conductivity and high temperature resistance play an important role.

Jewelry and Decorations

Some high-end jewelry and decorations are also made of tungsten silver alloy because this material is not only beautiful in appearance, but also wear-resistant and corrosion-resistant, making it very suitable for long-term wear.

When choosing tungsten silver alloy, it is necessary to consider the specific application scenario and performance requirements:

Composition ratio

Different proportions of tungsten and silver will affect the performance of the alloy. For example, alloys with high tungsten content are more suitable for high temperature and high pressure environments, while alloys with high silver content are more suitable for occasions with higher conductivity requirements.

Processing technology

Ensure that the supplier adopts advanced powder metallurgy technology and undergoes strict sintering and pressing processes to ensure the quality and performance of the alloy.

Application environment

Choose the appropriate alloy type according to the actual use environment (such as temperature, pressure, corrosiveness, etc.) to avoid performance degradation due to material mismatch.

Brand and certification

Choose a reputable manufacturer to ensure that the product meets international standards (such as ISO certification) and provides comprehensive after-sales service and technical support.

Cost and cost-effectiveness

The price of tungsten silver alloy is relatively high, so it is necessary to comprehensively consider the budget and performance requirements to select the most cost-effective solution.

Tungsten silver alloy has become an indispensable material in many high-tech fields due to its unique physical and chemical properties. From precision components in the electronics industry to high-temperature resistant components in aerospace, to high-precision parts in medical equipment, the application scope of tungsten silver alloy continues to expand, showing its huge market potential and technical value. With the continuous advancement of science and technology, the research and development and manufacturing processes of tungsten silver alloy will continue to be optimized, bringing innovation and breakthroughs to more industries. As a high-performance material, tungsten silver alloy will continue to promote the development of modern industry and contribute to the progress of human society.