Tungsten silver alloy is a composite material composed of tungsten (W) and silver (Ag). It has been widely used in many industrial fields due to its unique physical and chemical properties. This alloy combines the high strength and high melting point of tungsten with the excellent electrical and thermal conductivity of silver, becoming a high-performance material with both mechanical properties and functional properties.

The preparation process of tungsten silver alloy mainly relies on powder metallurgy technology, which includes the following steps:

Raw material preparation

Mix high-purity tungsten powder and silver powder evenly according to the designed ratio. In order to ensure the stability of the alloy performance, the particle size and purity of the powder need to be strictly controlled.

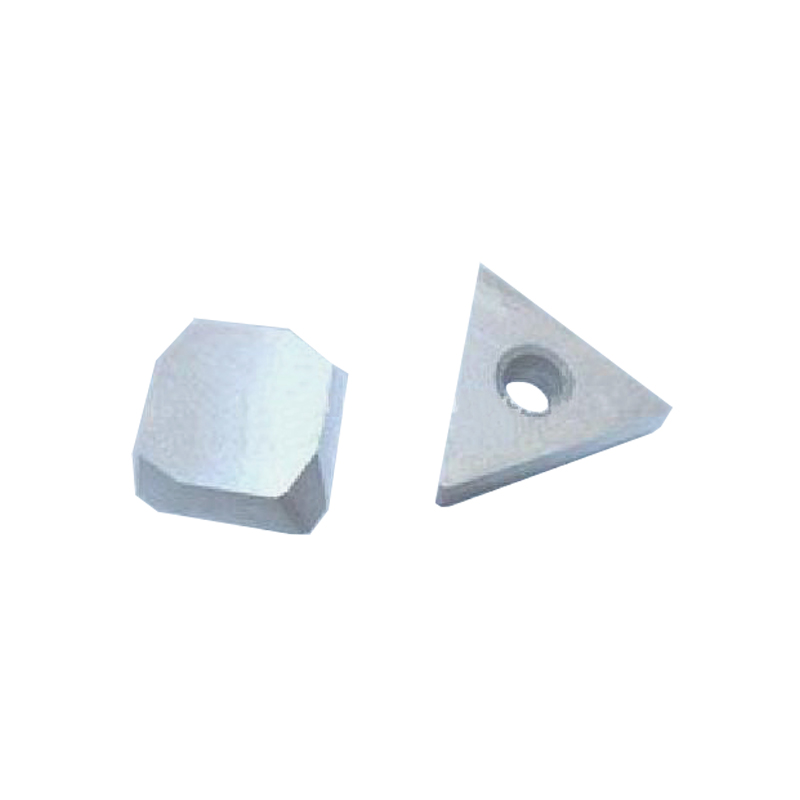

Pressing molding

The mixed powder is pressed into the desired shape, such as plates, bars or other complex parts. High pressure needs to be applied during the pressing process to ensure close contact between the powder particles.

Sintering treatment

The pressed blank is sintered at high temperature. The sintering temperature is usually lower than the melting point of silver, but sufficient to allow the silver liquid phase to flow and fill the gaps between the tungsten particles, thereby forming a dense alloy structure.

Post-processing

After sintering, tungsten silver alloy may require further processing, such as cutting, grinding or surface treatment, to meet specific application requirements.

Unique properties of tungsten silver alloy

The reason why tungsten silver alloy is so popular is mainly due to its significant advantages in the following aspects:

High strength and high hardness

The presence of tungsten gives the alloy extremely high strength and hardness, and can withstand greater mechanical stress and wear.

Excellent electrical and thermal conductivity

The addition of silver significantly improves the electrical and thermal conductivity of the alloy, making it outstanding in the fields of electrical and thermal management.

High temperature resistance

The high melting point of tungsten (about 3422°C) enables the alloy to maintain stable performance in high temperature environments and is suitable for extreme working conditions.

Arc erosion resistance

Tungsten silver alloy has excellent arc erosion resistance and can work stably for a long time under high frequency current and high voltage conditions.

Good processing performance

Although tungsten itself is difficult to process, tungsten silver alloy prepared by powder metallurgy technology has good processability, which is convenient for manufacturing complex parts.

Application fields

Due to its versatility, tungsten silver alloy has been widely used in many fields:

Electrical industry

In high-voltage switches, circuit breakers and contact materials, tungsten silver alloy is widely used due to its excellent conductivity and arc erosion resistance. It can effectively reduce the damage of arc to equipment and extend its service life.

Electronic industry

Tungsten silver alloy is used to manufacture semiconductor devices, integrated circuit lead frames, heat sinks and other components, giving full play to its thermal conductivity and electrical conductivity.

Aerospace

In the aerospace field, tungsten silver alloy is used to manufacture rocket nozzles, engine components and other structural parts that require high temperature resistance and high strength.

Welding and cutting

Tungsten silver alloy is often used in electrospark machining (EDM) electrodes and resistance welding electrodes, and is favored for its high temperature resistance and wear resistance.

Medical equipment

In the medical field, tungsten silver alloy can be used to manufacture X-ray shielding materials and radiotherapy equipment, taking advantage of its high density and radiation resistance.

Environmental challenges and future prospects

Despite the excellent performance of tungsten silver alloy, its production and waste treatment still face certain environmental challenges. For example, both tungsten and silver are rare metals, and over-mining may lead to resource depletion; in addition, the recycling rate of waste alloys is low. To this end, the industry is actively exploring more environmentally friendly solutions, such as developing alternative materials or improving recycling technology.

Looking to the future, with the advancement of science and technology, tungsten silver alloy is expected to be used in more fields. For example, the introduction of nanotechnology may further enhance its performance; the development of smart materials may also give it self-healing or adaptive functions. In addition, the popularization of green manufacturing concepts will drive the industry to develop in a sustainable direction.

Tungsten silver alloy has become an indispensable high-performance material for modern industry with its high strength, high conductivity and high temperature resistance. It not only provides reliable solutions for electrical, electronic, aerospace and other fields, but also lays a solid foundation for scientific and technological progress. In the future, with the continuous innovation of technology, tungsten silver alloy will surely make greater breakthroughs in performance optimization and environmental protection, and continue to contribute to the development of human society.