Tungsten silver alloy, a material known for its exceptional properties, is used in a variety of industries requiring high performance, durability, and precision. This unique alloy combines the remarkable characteristics of tungsten with the beneficial properties of silver to create a versatile material that is well-suited for demanding applications, particularly in the fields of electronics, aerospace, automotive, and electrical engineering.

The tungsten silver alloy typically contains between 90% to 98% tungsten, with the remaining percentage made up of silver. The exact composition of the alloy can be adjusted depending on the specific requirements of the application, such as the desired balance between conductivity and strength.

One of the most significant advantages of tungsten silver alloy is its excellent electrical and thermal conductivity. The inclusion of silver in the alloy provides superior conductivity compared to pure tungsten, making it an ideal choice for applications in electronics and electrical engineering, where efficient power transmission is required.

Tungsten silver alloys are commonly used in components such as electrical contacts, connectors, and switches due to their ability to handle high electrical currents without significant heat buildup or degradation.

Tungsten is renowned for its extremely high melting point of around 3,422°C (6,192°F), which is the highest of all metals. When combined with silver, the alloy retains much of this characteristic, making tungsten silver alloy suitable for use in high-temperature environments. This makes it ideal for applications in the aerospace industry and in components that are exposed to extreme temperatures, such as engine parts and heat exchangers.

Tungsten itself is one of the hardest metals known to man, and this hardness is retained in the alloy. Tungsten silver alloys are incredibly durable and wear-resistant, making them ideal for applications that require strength and resistance to mechanical stress. The alloy’s density also contributes to its robust mechanical properties, enabling it to withstand high-pressure environments without failure.

Silver’s natural corrosion resistance enhances the alloy’s overall ability to withstand oxidation and wear. Tungsten silver alloys are particularly resistant to corrosion in harsh environments, such as those involving exposure to chemicals, moisture, or high levels of electrical current. This makes them suitable for use in components that are exposed to challenging conditions.

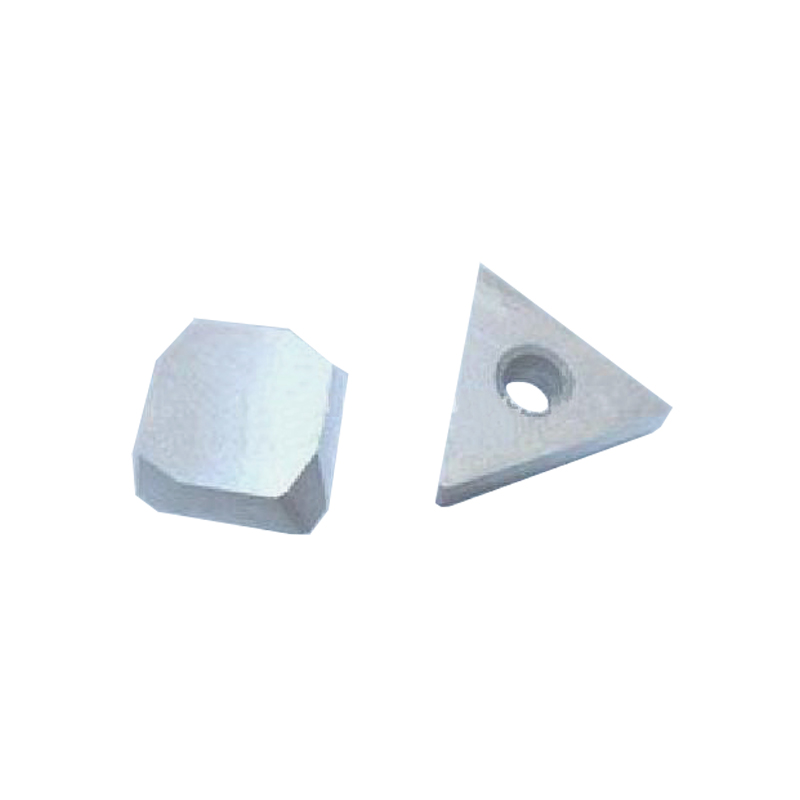

While tungsten itself is relatively brittle and difficult to work with, the inclusion of silver in the alloy improves its ductility and machinability. This makes tungsten silver alloys easier to fabricate into precise components and ensures that they can be easily processed using standard industrial techniques such as casting, molding, and milling.

Due to its unique combination of properties, tungsten silver alloy is used in a wide range of industries where both conductivity and strength are critical. Below are some key applications:

One of the most common uses of tungsten silver alloys is in the production of electrical contacts and switches. The alloy’s excellent electrical conductivity allows it to effectively transfer electrical currents, while its strength and durability ensure that the contacts can withstand the mechanical wear and tear associated with repeated use. Tungsten silver alloys are often used in high-voltage and high-current applications, such as circuit breakers, relays, and other electrical switching devices.

Tungsten silver alloys are also used in welding electrodes, particularly in applications where high-temperature resistance and electrical conductivity are required. These alloys are commonly used in the tungsten inert gas (TIG) welding process, which is used for precision welding of metals. The alloy’s ability to maintain its shape and conductivity at elevated temperatures makes it ideal for producing electrodes that are both durable and efficient.

In the aerospace and automotive industries, tungsten silver alloy is used in high-performance components that are exposed to extreme temperatures and mechanical stress. Examples include engine components, exhaust systems, and heat shields, where the alloy’s high melting point, strength, and thermal conductivity are crucial. Its resistance to wear and corrosion also makes it suitable for use in demanding environments such as space exploration and high-speed automotive applications.

Due to its high thermal conductivity, tungsten silver alloy is often used in heat sinks and thermal management systems in electronic devices. The alloy’s ability to quickly dissipate heat helps prevent overheating of sensitive components, ensuring that devices such as computers, LEDs, and power electronics operate efficiently and reliably.

In the semiconductor industry, tungsten silver alloy is used for interconnects, contacts, and lead frames in integrated circuits (ICs). The alloy’s combination of high conductivity and durability ensures that electrical signals are transmitted efficiently through the semiconductor, which is essential for the performance of electronic devices such as microprocessors and memory chips.

Tungsten silver alloy is widely used in the manufacture of electrical connectors and sockets. These components need to provide reliable electrical conductivity and mechanical strength over time, and the alloy’s properties make it an ideal material for such applications.

Tungsten silver alloys offer a unique combination of strength, conductivity, and durability, ensuring that components made from this material perform efficiently and reliably in demanding applications.

The material’s resistance to wear and corrosion enhances the lifespan of the components, reducing maintenance and replacement costs.

The alloy’s composition can be tailored to meet the specific requirements of different applications, offering flexibility in design and performance.