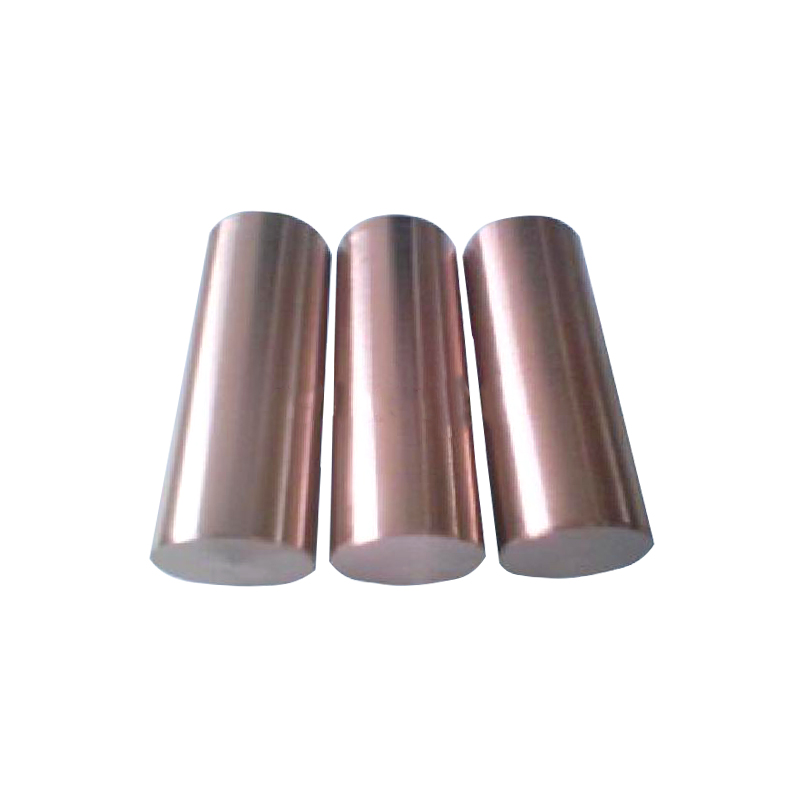

Copper tungsten alloy is a specialized composite material that combines the superior properties of copper and tungsten, creating a unique material known for its strength, thermal conductivity, and electrical properties. This alloy is primarily used in industries that require materials with high performance, durability, and resistance to wear and heat.

The composition of copper tungsten alloys can vary depending on the specific application, but typically, tungsten makes up between 60% and 90% of the alloy, with copper making up the rest. This combination imparts the material with unique properties, making it suitable for demanding applications in fields like electronics, aerospace, and manufacturing.

High Thermal Conductivity: One of the standout properties of copper tungsten alloy is its excellent thermal conductivity. Copper’s natural ability to conduct heat is enhanced by the presence of tungsten, making the alloy ideal for applications that require efficient heat dissipation. This property is particularly important in electronic devices and high-power components where heat management is crucial.

Electrical Conductivity: Copper is widely known for its high electrical conductivity, which is preserved in copper tungsten alloys. This makes the material ideal for electrical and electronic applications, particularly in situations where high power is needed, and electrical efficiency is essential.

High Strength and Hardness: Tungsten’s exceptional hardness and strength are imparted to the alloy, providing copper tungsten with a high resistance to wear and deformation. This makes the material ideal for applications involving heavy stress, high temperatures, and abrasion, such as electrical contacts and cutting tools.

Temperature Resistance: Tungsten has an extremely high melting point, which makes copper tungsten alloy highly resistant to high temperatures. This property ensures that the material can withstand extreme operating conditions without degradation, making it suitable for aerospace, defense, and high-performance industrial applications.

Low Thermal Expansion: Copper tungsten alloys have a low coefficient of thermal expansion, which means they expand and contract less with temperature changes compared to many other materials. This property is particularly valuable in applications requiring precise mechanical tolerances and stability over a wide range of temperatures.

Due to its combination of electrical, thermal, and mechanical properties, copper tungsten alloy is used in a wide range of high-performance applications:

Electrical Contacts and Switches: Copper tungsten alloy is widely used in the manufacturing of electrical contacts, especially in high-power switching devices such as circuit breakers and relays. The alloy’s ability to conduct electricity and resist wear and high temperatures makes it ideal for these applications, ensuring reliable performance in demanding environments.

Heat Sinks: In electronic devices, managing heat is essential to maintain performance and prevent damage. Copper tungsten alloy is often used in the production of heat sinks for electronic components, such as semiconductors and power devices, due to its excellent thermal conductivity and resistance to thermal fatigue.

Aerospace and Defense: Copper tungsten alloys are also used in aerospace and defense applications where high temperatures and mechanical stresses are common. The material’s high melting point, strength, and resistance to heat make it suitable for parts such as nozzles, connectors, and other critical components exposed to extreme conditions.

Semiconductor Manufacturing: The semiconductor industry relies on copper tungsten alloys for various parts of the manufacturing process. The material’s excellent thermal conductivity and strength are used in substrates for integrated circuits, where heat dissipation is critical to maintaining device efficiency.

Welding Electrodes: Copper tungsten alloy is used in the production of welding electrodes for applications that involve high temperatures, such as in arc welding. The material's resistance to wear and ability to maintain structural integrity at elevated temperatures make it ideal for these purposes.

Precision Tools and Cutting Dies: Copper tungsten alloy is used in precision tools, cutting dies, and molds, particularly in applications where high thermal and electrical conductivity is required. The alloy’s strength and wear resistance ensure that these tools maintain their performance even under intense conditions.

Enhanced Durability: Copper tungsten alloys are extremely durable, with high resistance to wear and tear. This ensures that components made from this alloy last longer, reducing the need for frequent replacements and enhancing the overall lifespan of products.

Improved Efficiency: The combination of high electrical and thermal conductivity makes copper tungsten alloys ideal for enhancing the efficiency of various devices and systems. This is particularly valuable in industries like electronics and aerospace, where energy efficiency is crucial.

Heat Management: With its superior ability to dissipate heat, copper tungsten alloy is an essential material for applications that require efficient heat management, such as in power electronics and high-speed machining.

Customization: The composition of copper tungsten alloys can be tailored to meet the specific needs of different applications. By adjusting the ratio of copper to tungsten, manufacturers can customize the material's properties to suit a wide range of demanding environments.